Allergy Force met Dr. Steven Gendel PhD at a FARE Summit. Dr. Gendel is the Senior Science Manager – Foods at USP (United States Pharmacopeia), a non-profit organization dedicated to help protect and improve the health of people around the world. The USP plays a critical role in publishing ingredients standards in the Food Chemicals Codex (FCC), producing reference materials, providing consulting and training on food fraud vulnerability assessment & mitigation, and publishing a food fraud database.

Previously, Gendel was the Food Allergen Coordinator for the FDA, where he led policy initiatives, developed regulatory documents and assisted in enforcement activities. He has over 25 years of experience in food safety, has published over 90 technical publications, has held postdoctoral positions at Harvard and University of Toronto, and was on the faculty of the Iowa State University Department of Genetics.

During the FARE Summit, Gendel shared an eye opening presentation on ‘Behind the Label: Understanding Food Labeling Laws, Manufacturing and Risks’. There’s a lot to know about U.S. food labels and manufacturing practices. With food allergies what you don’t know can hurt you, even kill you.

History that shapes today’s ‘life with food allergies’

When introduced in the 1960’s, food labels were not designed to be risk management tools. They were originally developed for nutritionists, to supply nutritional information. Besides, food allergies were barely a blip on the horizon at that time.

The Food Allergen Labeling and Consumer Protection Act (FALCPA) of 2004 amended the Food, Drug and Cosmetics Act that regulates food safety in the United States. FALCPA (effective January 1, 2006) is a U.S. law that requires all food labels in the U.S. to list ingredients that may cause allergic reactions. FALCPA falls under the FDA. The USDA, which regulates meat, poultry, and some egg products, followed the FDA’s lead. Note that alcohol is not regulated by the FDA. Alcohol is regulated by the Alcohol and Tobacco Trade and Taxation Bureau under the Treasury Department and does not have the same labeling requirements as the FDA.

While individual ingredients can obtain exemptions, the FDA cannot simply add a new major food allergen (MFA) to the list of top allergens called out on food labels; amending the list of major food allergens requires an act of Congress.

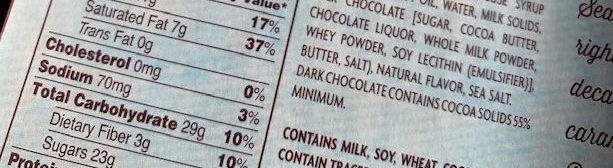

When you read a food label: what you need to know

With the increasing prevalence of life-threatening food allergies, consumers use food labels to make risk management decisions – each and every day — based on the wording they see and their interpretation of that wording. Gendel highlighted the following during his presentation:

- Ingredients on a food label are listed in descending order by weight.

- Under FALCPA, MFA’s were identified and defined, and include the Big 8 — milk, eggs, fish, crustacean shellfish, tree nuts, peanuts, wheat and soybeans.

- Any ingredient containing a protein from one of the Big 8 is also considered an MFA and must be disclosed.

- Fish and Shellfish must be specifically identified.

- Highly refined oils made from an MFA (e.g., refined peanut oil) are exempted. While labels must disclose what kind of oil is used, the oil does not have to be listed as an MFA.

- Regulatory ‘common and usual names’ may not be the same as Consumer ‘common and usual names’ for allergens. For example, Casein is the main milk protein and ‘Casein’ is not a ‘common and usual name’ for consumers.

- Food manufacturers are allowed to spell out common allergens next to the allergen containing element, OR use a “Contains” statement.

However, consumers — beware!

What you think you read and what the industry thinks it is telling you are very different things. For example, how do you evaluate contamination risk when you see a product was ‘Manufactured/Made in the Same Facility’ with your allergens? How do you evaluate contamination risk when you see a product was ‘Manufactured/Made on the Same Line/Equipment’ as your allergens? Or when you see a “May Contain” statement?

Here’s why:

When food is ‘Manufactured/Made in the Same Facility’, what does this really mean? Does the manufacturer have two different lines in the same room? Two different lines in two different, but adjacent rooms? Two different lines in different physical locations separated by some distance? The risk levels are different, but the disclosure is identical. And where do the employee lunchroom and break room vending machines fit into the mix? Are employees allowed to bring allergen-containing products into the manufacturing facility to personally consume? Are PBJ sandwiches lurking in employee lunchboxes? What control measures are in place to prevent those allergens from coming into contact with the manufactured products? The only way you can evaluate the risk is by calling the manufacturer and getting the facts.

When food is ‘Manufactured/Made on the Same Equipment’ what does this tell you? How is the equipment cleaned between production runs? According to Gendel, proteins are ‘sticky’, difficult to remove from food contact surfaces, especially if the protein has been heated. Is equipment cleaned between runs using a water rinse? A sanitation cleaning? Or, a full allergen cleaning? Again, the contamination risk levels vary by cleaning method, but the disclosure is identical. The only way you can evaluate the risk is by calling the manufacturer in search of answers.

FALCPA also does not regulate the ‘May Contain’ statement, though the statement must be truthful and not misleading. The ‘May Contain’ statement is inherently ambiguous and is dependent upon companies’ food safety and allergen control process and procedures. In research completed by Malyukova, Gendel and Luccioli in 2013-2014, 47% of food recalls were caused by undeclared allergens.

As an ‘at risk’ food allergic consumer, you can’t really know what food labels are telling you about the risk of consuming a product. The only way you’ll know what is going on at a manufacturer’s production facility is by calling the manufacturer and asking questions.

Some important takeaways from Gendel’s presentation?

- Be quick to pick up the phone and contact manufacturers regarding their labeling if it’s a product you want to buy.

- Pay close attention to recalls.

- Be a vocal consumer—providing input when regulatory agencies request comments on proposed changes to food labeling rules and regulations, if not directly, then via advocacy groups like FARE, FAACT, and KFA.

Image Credit: Image by Allergy Force